yakapetwa kaviri kutenderera mutsara wepamusoro girazi kupedzisa T yekufambisa tafura

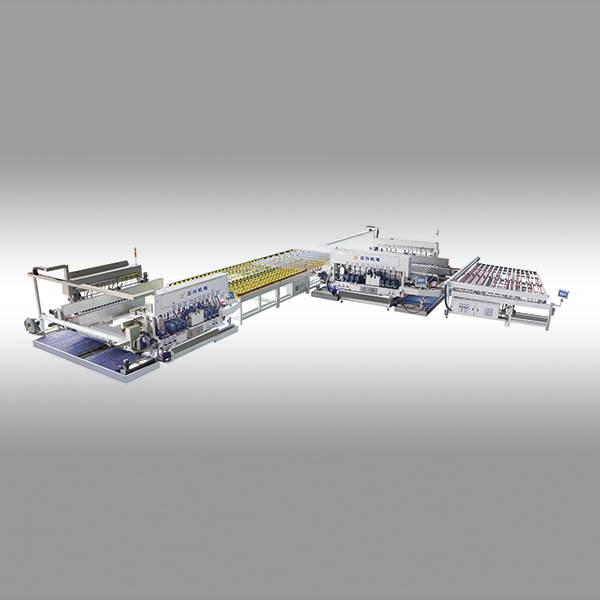

FH4225 SM2242GT + ZT4225 + SM2225GTS

Dzora komputa

Nomazvo servo kuyera hurongwa

upamhi hwekugadzirisa system

Yakakwira mhando yemagetsi zvikamu

Pneumatic makorari system

Arris mota

Yakakwira kunyatsoita tafura yekuchinjisa

Yakakwira kunyatsoita tafura yekuchinjisa

Muchina Nhanganyaya

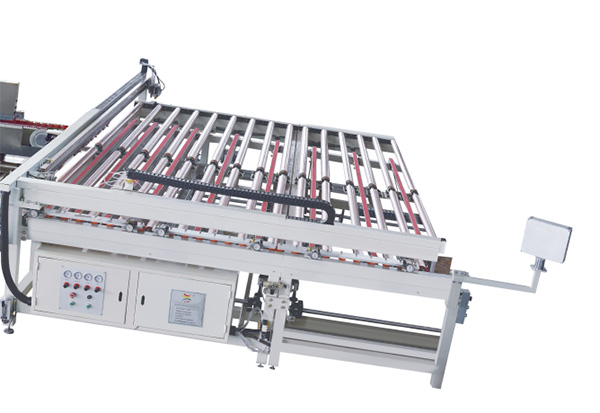

Tafura yegirazi yekuyera

Dhiraivha system

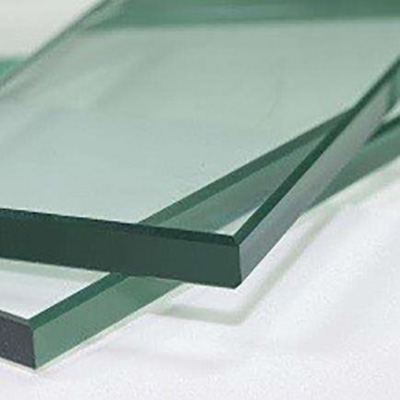

Iyo midziyo inoshandiswa kuendesa uye kuisa girazi kuti rishandiswe, ita chiyero chakaringana chehurefu, hupamhi uye ukobvu hwegirazi, uye kuendesa iyo data kune maviri-kumucheto grinder uye imwe yekugadzirisa michina yekuenderera mberi girazi kugadzira.

Kuvakwa kwetafura yekuyera yegirazi kunosanganisira zvikamu zvina senge pazasi:

1. Positiong tafura

Kuendeswa kwegirazi kuenda kumberi kana kudivi kunotyairwa ne frequency converter uye shanduka frequency frequency mota. Yekumhanyisa kumhanya inogona kugadziridzwa. Positioning chaiyo ne yepamusoro sensors. Kureba, upamhi uye ukobvu hwegirazi zvinogona kuyerwa mushure mekumiswa kwakakodzera.

2. Kuyera mudziyo

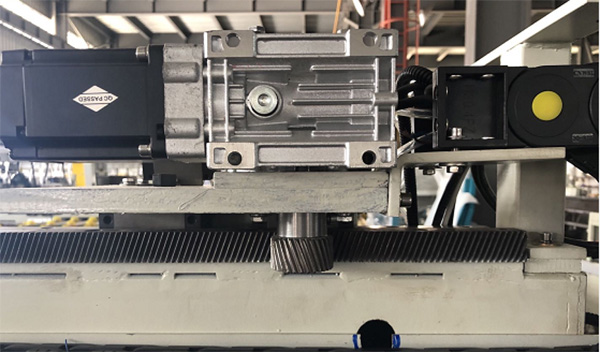

Ukuru hwehurefu hwegirazi uye upamhi hunoyerwa neyakanyanya giya dhiraivha yekunzwa inotyairwa neservo mota. Iko kukura kwegirazi kukora kunoyerwa nesirinda inotyairwa neyiloni block kumanikidza pagirazi pamusoro uye encoder inotyairwa negiya. Iyo humburumbira kumanikidzwa inogadziriswa zvakasiyana.

3. Electrical kudzora system

ECS ine programmable controller (PLC), inobata skrini (HMI), servo driver, servo mota, frequency converter, frequency kutendeuka mota, sensor, nezvimwewo PLC inodzora muchina kuti ushande otomatiki zvinoenderana nehunyanzvi hwekugadzirisa. HMI inopedzisa iyo yemunhu-komputa yekudyidzana basa.

4. Software sytem

Iyo software sisitimu inofanidza iyo data kubva pagirazi yekuyera tafura nedhairekodhi data, uye inowirirana otomatiki kune yepedyo girazi dhata. Zvichakadaro, iyo girazi data inopfuudzwa kune yakapetwa kumucheto grinder uye imwe yekugadzirisa michina yemodi kana batch kugadzirwa.

Uchishandisa princple:

Nemaoko kana otomatiki isa rimwe chete girazi pagirazi yekuyera girazi. Tafura yegirazi yekuyera inoratidza, chinzvimbo uye nekuyera chaizvo kuyerwa kwehurefu hwegirazi, upamhi uye ukobvu. Yakayera girazi dhata inopfuudzwa kune manejimendi sisitimu yekuenzanisa kuenzanisa iyo yekura data uye inopfuudzwa kune yakapetwa kumucheto grinder uye zvimwe zvekugadzirisa zvishandiso zvemberi girazi kugadzira. Inotevera imwe chete girazi regirazi inoiswa patafura yegirazi yekuyera uye wotanga kunotevera kutenderera kutenderera.

2. Girazi yakatwasuka mutsara wakapetwa kumucheto polishing machine.

Muenzaniso Nha .: SM2242GT SM2225GTS

Muchina uyu wakagadzirirwa kupukuta mativi maviri akatarisana egirazi panguva imwe chete.

Kudzora

Muchina uyu unotora yeJapan Mitsubishi PLC kutonga uye gumi ”opareta interface. Iyo Screen inoratidza yega yega yakajeka parameter yegirazi. Muchina wega wega unogona kudzorwa nekombuta yayo kana kudzorwa nekombuta hombe.

Kodzero yemushandisi inogona kuverengerwa seanoshanda / kugadzirisa / maneja, kudzivirira kukanganisa kuitika, chengetedza muchina kubva mukusaita mushe.

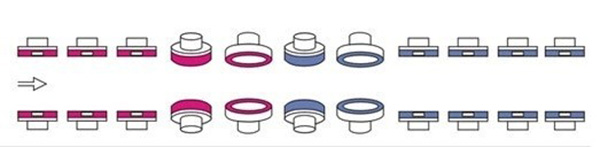

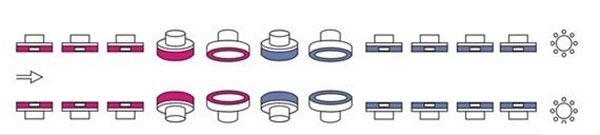

b) Kutungamira kwepamusoro.

Iwo maviri mabhandi ekufambisa nguva anofambiswa nemaviri servo motors, ane chimiro cheiyo chaiyo chaiyo, kumhanya kwakanyanya, kuwiriranisa kwakakwirira.

c) Nhare yekukuya chikamu kufamba.

Iyo nhare yekugaya chikamu inofamba ichiteedzana twin twin bhora rinotakura gwara. Iyo yekufambisa inoitwa kuburikidza nebhora screws, iyo inotyairwa neservo mota, iyo Max inofamba yekumhanyisa yekugedza chikamu inogona kusvika gumi nemashanu paminiti. Iyi sisitimu zvakare inosanganisira brake uye inobata sisitimu, iyo inogona kuvimbisa kugadzikana kwekufamba kwechikamu chekukuya, yakaderera simba simba. Iyi ficha inogona kuvimbisa kugadzikana kwesimba rinobata girazi rakakura saizi, kunyangwe mushure memuchina unomhanya kwenguva yakareba.

d) Yega yega edger ine imwe autoamtic yepakati rutsigiro njanji, iyo inofamba pamwe chete nechinofamba chikamu chinosemesa, icho chinotsigira girazi kubva panzvimbo yepakati kudzivirira girazi kubva mukukotama. Kune yakakura kwazvo saizi edger yakapetwa, isu tinopawo imwe inotakurika njanji yekutsigira, iyo inogona kuiswa nemaoko ichida.

e) Yakakwira track kumusoro & pasi sisitimu shandisa inotsvedza dhizaini dhizaini isina kunamira dambudziko iyo yechinyakare inotsvedza sleeve system

f) Positioning system.

Girazi kurodha chinzvimbo system inosanganisira zvikamu zvina: zvakagadziriswa rollers, inofamba mweya inobata sisitimu, yekumisa mabhuru (imwe kuruboshwe uye imwe kurudyi), kumusoro mhepo ichimanikidza rollers (imwe kuruboshwe uye imwe kurudyi). Girazi rakanyatsoenderana uye rakadzvanywa zvine simba neiyo yekumisikidza system. Iyi sisitimu inovimbisa kukuya kwakaringana uye kupora maturo.

g) Kugadziridza kuri nyore

Iko kusimudza / kudonhedza kwepamusoro yekutevera system uye epamusoro arris mota inofambiswa nemota. Inogona kuiswa otomatiki maererano akasiyana girazi ukobvu.

h) Sisitimu yeMhepo.

Vhiri rinobwinyiswa rinoshandiswa nemhepo, iyo inodzorwa ne PLC uye yemagetsi vharuvhu, iyo inogona kufamba kumberi / kumashure maererano negirazi chinzvimbo. Iyi sisitimu inokwanisa kutsiva kusakara kwemavhiri, ichipa kumanikidza kusingagumi kugirazi uye kuwana mhedzisiro yakafanana yekukorobha.

Iyo yekupukuta mota inofamba sisitimu inoshandisa Yakanyanya kunyatsoita dural linear slide njanji system.

i) Pasi uye furemu:

Yakagadzirwa nesimbi gobvu yakagadzirwa, iyo inorapwa neannealing vira mufekitori yedu. With zvakanaka kugadzikana uye Anti-torsional simba, Anti-vachikotama simba.

j) Motokari

Shandisa yakakwira kunyatsoita, yakaderera vibration ABB kusiana frequency mota. Iyo mota yekumhanyisa inogona kuwedzerwa kusvika ku4200RPM kuburikidza neiyo frequency inverter, muchina unoshanda kumhanya unogona kuwedzerwa kusvika makumi maviri emamita / miniti.

Iyo mota yekudzivirira system ine chengetedzo basa rekuwandisa / kushaya chikamu / pfupi dunhu, zvemagetsi zvikamu zvinoshandisa nyika nyowani mhando, yakajairwa mhando, inogona kuwanikwa zviri nyore mumusika, izvo zvinoderedza mutengi wekuchengetedza mutengo, zvinowedzera kugadzirwa kwekuita.

k) Kumusoro / Pazasi Kutumira conveyor tora nguva mabhandi.

l) Mafuta:

Iwo mapatya bhora akatakura mitsara sikuruwa uye nhungamiro njanji dzakakwenenzverwa ne otomatiki pombi yemafuta.

Muchina wacho zvakare wakagadzira pombi yekugadzirisa pombi, inozodza iyo inotsvedza pamusoro.

m) Kushanda kumhanyisa kugadzirisa: Kuburikidza ne frequency frequency inverter.

n) Tangi remvura, tireyi yemvura, yepamusoro / yepasi nguva yekuvhara bhandi, mitsara yakatungamira njanji / bhora sikuruu zvinoitwa musimbi isina chinhu.

o) Amperometer mita:

tarisa vhiri assortion.

Mamwe mashoko mapikicha.

Pakona akacheka kukuya mota

Kutsiva-inoshanduka isina mvura isina kubatanidza module dhizaini chinonzwisisika chiratidzo cheiyo yepamusoro uye yakadzika arris mota ampermeter.

3. L- chimiro Chinjana tafura. Roller tafura uye bhandi yenguva.

Muchina uyu unoumbwa ne roller kutenderera system uye nguva yebhandi kutumira system. Iyo roller inotumira system inotyairwa necheni, kumhanya kwakapindirwa ne inverter accoring kune iyo yekumhanyisa kumhanya.

Nguva yebhandi inotumira system inogona kusimudza uye kudzika pasi. Kana girazi rikabuda kubva kune yekutanga edger, iyo nguva bhandi system ichasimudzwa. Girazi rinoendeswa kurudyi positon uye zvobva zvadzikiswa pasi pane roller inotumira system.

Nguva yebhanhire conveyor system inoshandisa aluminium muviri muviri.

Technical parameter

Yekumhanyisa mhanyisa

| Chinhu | Girazi ukobvu | Max. kushanda kumhanya | Girazi Kupedza |

|

1 |

4 - 6 mm | 22 m / min | Kukuya zvakaipa |

|

2 |

8 -10 mamirimita | 18 m / min | Kukuya zvakaipa |

|

3 |

12 - 15 mm | 15 m / min | Kukuya zvakaipa |

|

4 |

4 - 6 mm | 16 m / min | Kwakaisvonaka makorari |

|

5 |

8 -10 mamirimita | 14 m / min | Kwakaisvonaka makorari |

|

6 |

12 - 15 mm | 12 m / min | Kwakaisvonaka makorari |

Kushanda nemazvo:

| Chinhu | Tsananguro | Nemazvo Range |

|

1 |

Diagonal mutsara kunyatso | ≤0.5mm / m |

|

2 |

Kufanana kwakaenzana | ≤0.2mm / m |

|

3 |

Saizi saizi chaiyo | ≤0.2mm / m |

|

Chinhu |

Parameter | Range |

|

1 |

Max. saizi yegirazi | 4200x2500 mm |

|

2 |

Min. saizi yegirazi | 350 x 350 mm, singe yakapetwa kaviri isina bracket yepakati400 x 400 mm - mutsetse wese) |

|

3 |

Girazi ukobvu | 3 - 28 mm |

|

4 |

Upamhi hweArris: | 1 - 3 mm |

|

5 |

Kukuya kudzika | 3 mm (rimwe divi) |

|

7 |

Upamhi hwekugadzirisa nekukurumidza | 1 - 15 m / min |

|

8 |

Kushanda mweya wekumanikidza | 0.7 MPa |

| Kushanda kureba: | 920 - 960 mm | |

|

9 |

Simba rakazara | Kunenge 135 KW / 380V 50Hz 3P |